Cutting Services

Water Jet

Why water jet cutting?

We have a state-of-the-art water jet cutting machine which is capable of cutting any material up to 150mm thick. The machine also benefits from a two meter by four meter bed. Examples of materials which can be cut include stainless steel, aluminium, copper, brass, wood, ceramics, concrete, plastics and nylon.

Water jet over laser?

The water jet has many benefits over conventional laser profiling methods:

- There are no heat affected zones, as it is a cold process.

- There is no tool contact, and therefore no edge deformation.

- Materials from thin shim to 150mm thick can be profiled.

- Virtually any material can be cut, though we are unable to cut toughened glass as it has the tendency to shatter. It is possible to cut normal glass and have it toughened afterwards.

- Clean, accurate process.

- No tooling cost.

- Secondary cleaning operations are reduced or eliminated.

- No restriction on hole sizes.

- Little to no burr.

- Capibility to cut extremely detailed geometry.

- Very little side force is placed on the material whilst cutting, allowing delicate parts to be cut.

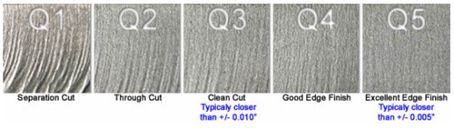

- With water jet machines you have a choice of the level of edge quality you require.

The above image shows the edge qualities we can achieve. Our standard cut is a Q3.

Abrasive waterjets cut material from 1/16 inch to 6 inches thick, in high or low volume. Typical part tolerances range from between 0.003" and 0.005" of an inch, although tolerances as close as 0.001" of an inch can be achieved as well. There is absolutely no mechanical stress, heat distortion or heat-affected zone, and secondary processing can be eliminated in many cases.